The Test With Burn-In Company

Micro Control Company is the worldwide leader in burn-in with test systems. Micro Control offers solutions for high-power burn-in test applications requiring individual temperature control and logic/memory burn-in test applications for lower power devices.

Burn-In Systems

Micro Control Company’s burn-in systems feature a pattern zone per slot, multiple temperature zones and independent temperature control per DUT. With up to 64 M of vector memory behind all 128 independent I/O channels, Micro Control Company systems can handle many different functional tests.

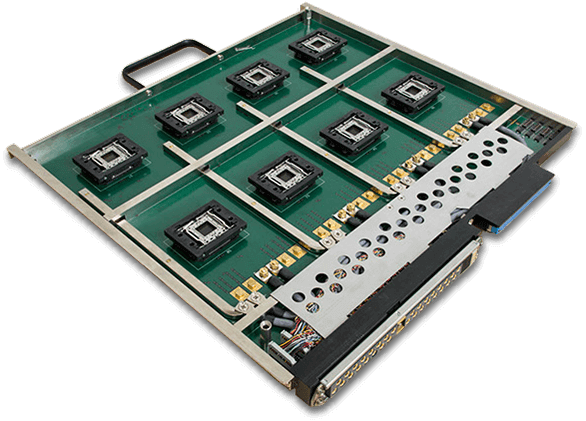

Burn-In Boards

Flexible designs to take advantage of features including high speed clocks, individual current monitoring, and tight pitch sockets.

MicrO Control Company is the worldwide leader of burn-in with test systems.

focused on the future

At Micro Control Company, our employees are challenged to innovate and learn something new every day. We believe that constant evolution is the key to long-term success. Our engineers design each system with the customer in mind; both for current needs and the needs of the future.