History:

Harold Hamilton

Harold Hamilton founded Micro Control Company in 1972 as a manufacturer of test equipment for the electronics industry. The microprocessor-controlled test system produced in 1973 was the first in the industry. Today, the tradition continues with Micro Control Company’s high-power burn-in and test systems which are being shipped to customers throughout the world.

Along with high-power burn-in systems for logic and memory applications, Micro Control Company designs and builds burn-in boards and other burn-in accessories for use during reliability or production burn-in applications.

Why Micro Control Company?

Quality

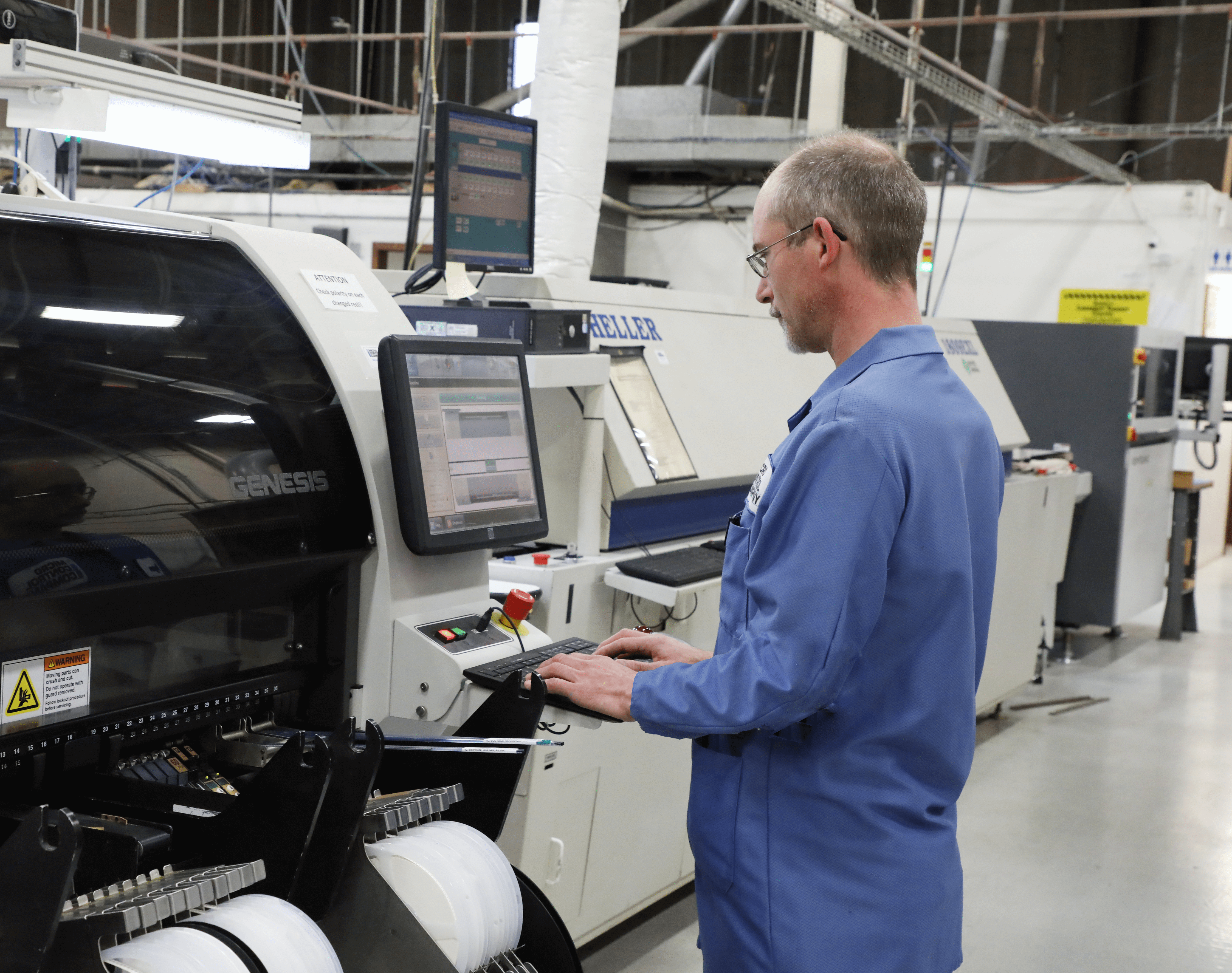

In the 50 years since Micro Control Company was established, a commitment to high quality products has always remained a top priority. We strive to exceed our customers needs by creating an environment focused on excellence. Each and every employee is committed to innovation and improvement. Every system and burn-in board is made from the highest quality components and is rigorously tested prior to shipment.

Customer Service

Here at Micro Control Company, we place a premium on customer service; helping you achieve your goals allows us to achieve ours. From your first sales inquiry to post-install, our team seeks to help you understand and get the most out of your burn-in with test system.

Focus on Engineering

Unique solutions through innovative designs allows Micro Control Company to continue to meet the challenges of the semiconductor industry. At the center of our operations, a talented team of engineers provide the knowledge and experience to meet customer-specific application requirements. By working together, we will find the right burn-in solution to meet your needs.

Industry First

Micro Control Company prides itself on leading the industry in providing unique solutions to test and burn-in with test challenges. Over the years, Micro Control Company has been the first to bring these innovative designs to market, carving a niche for itself as the test with burn-in company.

Discover Our History

1973

First microprocessor-controlled test system is created by Micro Control Company founder, Harold Hamilton.

1974

First single-range programmable clock edges.

1976

First memory burn-in test system with algorithmic pattern generation.

1977

First system able to test for alpha particle sensitivity.

1981

First large-scale 10-MHz memory burn-in test system (6,912 devices).

1984

First parallel memory burn-in test system (1,728 devices tested simultaneously).

1986

First 15-MHz environmental test system.

1989

First 256-pin I/O burn-in test system for VLSI devices.

1991

First logic burn-in system using ASIC technology.

1992

First burn-in system using weighted random patterns.

1994

First memory burn-in and test systems using ASICs.

1997

First large-scale high-power burn-in system.

1997

First massively parallel memory test system used in manufacturing for batch testing.

1998

First 200 MHz memory test system.

1999

First burn-in test system for 200-watt devices with individual temperature control provided to each device.

2001

First air-cooled burn-in with test system for 75-watt devices with individual temperature control for each device.

2001

First burn-in with test system capable of full testing of logic and memory devices.

2004

First burn-in with test system for 600-watt devices with individual temperature control.

2005

First air-cooled burn-in with test system for 150-watt devices with individual temperature control for each device and an individual pattern zone per burn-in board.

2008

First low cost burn-in system with individual temperature control.

2012

125 Amp regulators

2013

HPB-4 High Force trays

2014

+- 150 Volt regulators

2016

1,000 Volt LC2 applications

2020

HPB-5C+ system is released.

2020

First fully automatic system is released; the LC-2 Automation system.

2021

LC-2+ system is released.

2023

First burn-in with test system for 1000-watt devices with individual temperature control.